General

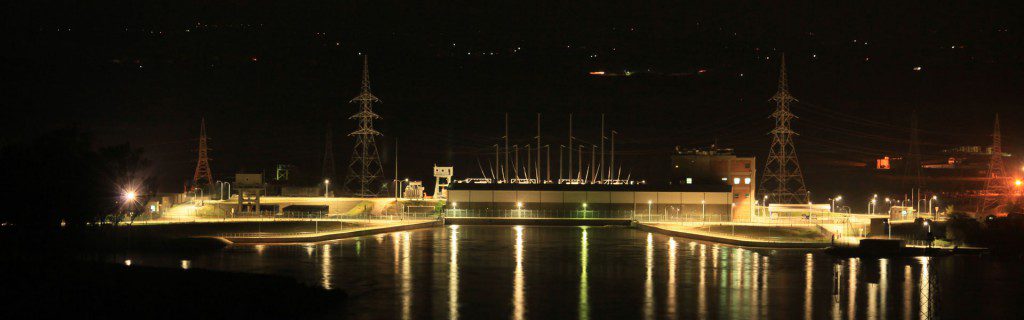

- First independent hydropower producer (IPP) in Pakistan/AJ&K;

- Installed plant capacity of 84 MW;

- Annual electricity generation of 540 GWh based on historic hydrology; annual Take-or-Pay level 470 GWh;

- Situated near the New Bong Escape, some 7.5 Km downstream of the Mangla Dam and 120 km from Islamabad capital city of Pakistan;

- Developed under B.O.O.T mechanism and to be transferred free of cost to the Government of AJ&K at the end of the 25 year term;

- Commercial operations commenced on 23rd March, 2013.

Development Impact

- Created a framework for hydro IPPs with a strong demonstration effect (standards, procedures and document prototypes established in this Project are being replicated in other hydro projects in the pipeline);

- Reduced the level of very costly electricity and meets incremental demand for power, thereby encouraging economic growth;

- Contributed to increase the country’s much needed installed capacity using a domestic renewable resource, thereby increasing energy security of supply;

- Contributed to lowering the average economic cost of power generation in Pakistan;

- Has significant environmental benefits compared to alternative thermal power options in terms of displacing greenhouse gas emissions (estimated reduction of greenhouse gas emissions is 218,000 ton CO2 equivalent per year);

- Creation of about 300 to 500 skilled and unskilled jobs during the Project construction phase and more than 150 jobs on an ongoing basis during operational period; and

- Reduced reliance on imported fuel oil, thereby not impacting the country’s trade and current account deficits.

Financial

- Total Project cost is estimated at about US$ 235 million and financing is arranged at debt equity ratio of 75/25;

- Debt financing in US$ provided by ADB, IFC and PROPARCO;

- Debt financing in PKR provided by NBP and HBL;

- IDB provided financing for the equipment under ijara facility;

- 74.95% of Project equity is held by HUBCO while remaining 25.05% is owned by other shareholders including Coate & Co (Pvt) Ltd;

- The Levelized Reference Tariff (at financial closing) US cents 8.5453/KWh;

- Energy above 470 GWh will be paid at a special rate of 10% of the prevailing tariff;

- Hydrological risk borne by the power purchaser through guaranteed payment/ Take or Pay for 470 GWh per annum;

- The Project is registered as CDM Project with UNFCCC;

Project Security

- A comprehensive concession documents/security package in place.

- Concession Documents package includes long term Power Purchase Agreement with NTDC, GOP Implementation Agreement with Government of Pakistan, AJ&K Implementation Agreement with AJ&K Entities (i.e. Government of AJ&K and AJ&K Council), Water Use Agreement with Government of AJ&K;

- Government of Pakistan has provided GOP Guarantee which guarantees the payment obligations of NTDC, GOP and GOAJK;

- 25 years Power Purchase Agreement provides tariff adjustment mechanism for:

- changes in US$/Rupee exchange parity for all US$ components of tariff;

- changes in interest cost due to variation of LIBOR/KIBOR interest rates;

- changes in inflation for O&M component of tariff;

- changes in civil works material like cement, steel, fuel and labour during construction period;

- changes in customs duty, resettlement cost and interest during construction.

- Implementation Agreements provide package of incentives like protection against political force majeure, protection against changes in law, tax and other fiscal concessions and protection of water rights.

Hydrology

- Well-regulated and dependable water releases through Mangla Powerhouse into the Bong canal available to the Project after satisfying the Upper Jhelum Canal (UJC) indent;

- Hydrological data is maintained by the Mangla Dam Organization for past 81 years providing a sound and reliable hydrological basis for energy estimation and high degree of assurance to the Power Purchaser as basis for the committed minimum energy payment;

- Mangla Dam Raise Project (raising the storage of Mangla Reservoir from 4.7 MAF to 7.6 MAF) completed in 2010 and has further strengthened and regulated Project’s hydrology and water flow.

Technical

- The Project layout is defined by site constraints such as the Jhelum River, the New Bong Escape, the Old Bong Escape, Upper Jhelum Canal Head Regulator and the three power transmission lines at the Site. All the Project components are located between the New and Old Bong Escapes.

- Main Project components are as follows:

- A concrete lined Headrace channel to convey the water from Bong Pond to Powerhouse.

- The semi submerged type powerhouse complex that houses four sets of bulb turbines and generators, and associated electrical and mechanical systems.

- Tailrace Channel is about 6.5 km long and 400 ft wide at bed, is primarily required to gain the additional head at Powerhouse by excavating the natural steeper river bed on less steep gradient

- The GIS type switchyard is providing connectivity with the existing 132 kV system through an in-out arrangement on the 132 kV Mangla-Kharian transmission line passing over the Project site

Environment

- The Project is considered environment friendly with minimal environmental and social issues. Because of limited number of specific environmental and social impacts the Project has been classified as category B both by IFC and ADB.

- The limited number of environmental and social impacts can be avoided or mitigated by adhering to generally recognized performance standards, guidelines or design criteria.

- The Project is a run-of-the-river hydropower plant and does not involve any new dam or reservoir. It will utilize surplus water currently being discharged from the existing upstream 1,000 MW hydropower complex located at the Mangla Dam, which will improve downstream water resource utilization efficiency.

- The Project will not cause any change in the irrigation water availability of the downstream areas, nor will it result in the physical or economic displacement of downstream communities.

- The Company conducted updated environmental and social assessment to demonstrate that the Project design is in accordance with the IFC’s Performance Standards on Social and Environmental Sustainability on April 30, 2006.

Construction Arrangements

The Project has been constructed under a lump-sum (only civil works cost escalation is allowed), fixed-price, date-certain turnkey EPC contract. Following a transparent competitive bidding process the EPC Contract was awarded to Sambu Construction Company Limited of South Korea. Sambu has extensive experience of constructing a number of dams and associated hydropower projects. Andritz Hydro, as a subcontractor of EPC Contractor, is the supplier of E&M equipment on water to wire basis. Hyundai Engineering is the design subcontractor of the EPC Contractor.

Operational Arrangements

Hub Power Services Limited (HPSL), a wholly owned subsidiary of The Hub Power Company Limited (HUBCO) is currently the O&M operator for the Project. HPSL offers core services and support in the repair and scheduled maintenance of the plant. HPSL has sufficient experience in operating and maintaining power plants and is involved in O&M of 2 other power plants in the group namely Narowal plant and Hub Plant.